ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreVertical Seal Wrappers Multipacking Machinery Solutions

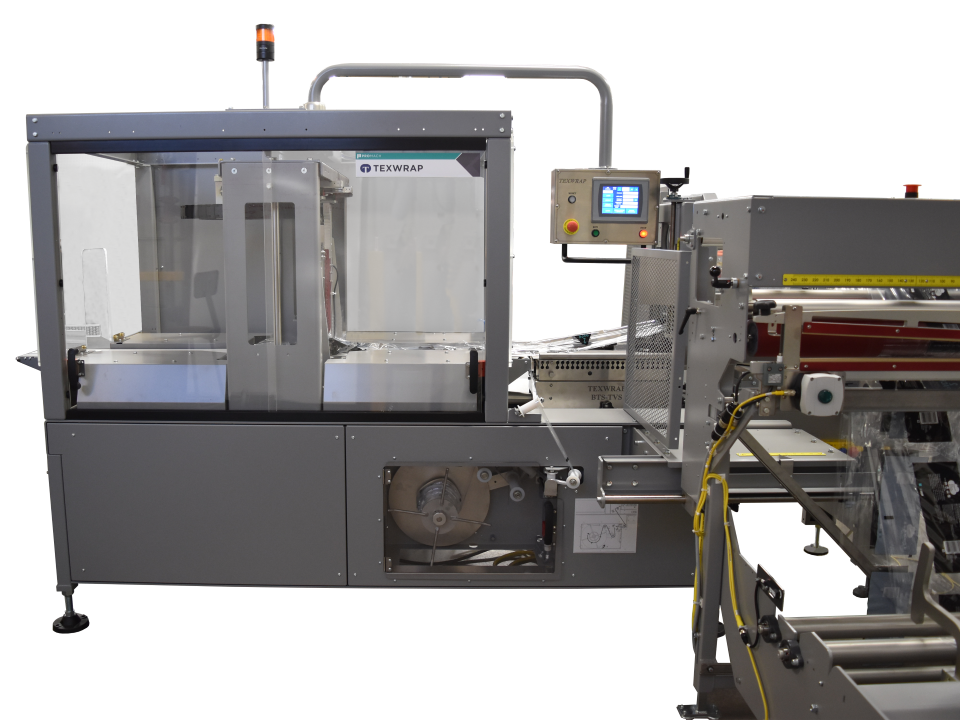

Vertical seal wrappers encapsulate products in a continuous tube of film similar to side seal wrappers, sealing along one side of the package and then separating them into individual units downstream using a cross seal. Unlike side seal wrappers, vertical seal wrappers feed product vertically into the wrapper eliminating the need to transition products to a horizontal position.

Vertical seal wrappers are designed for products in a variety of pack patterns, including:

- Using a full top trim seal

- Multipacking

- Variety packs

Contact Texwrap to learn more about the vertical seal wrapping solutions.

The BVS Vertical Sealers are ideally suited to multipacks or variety packs that exit upstream equipment in a vertical position. A vertical multipacker provides packagers with a way to shrink wrap these packs without the labor and expense of laying them down prior to wrapping on side sealing systems.

The OVS Series machines are similar to the BVS series in that they are able to accept products in a vertical or upright position eliminating the need to lay them down. It uses a full top trim seal instead of a lap seal to securely enclose the product. Often used as a multipacker for retail sale, the precise product and film control of the OVS series provides our highest rate of operation with precise print registration.