ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFeatures & Specs

- Ability to accommodate a wide range of product sizes

- SmartTrack helps prevent order fulfillment errors

- Speeds of up to 20 mailers per minute save on both labor and time

- Advanced photo eyes accurately measure the product dimensions to create the perfectly sized mailer every time

- Saves on manual packing labor costs

- Significant savings vs pre-made bags

- By minimizing the amount of packaging used, dimensional weight freight costs are reduced

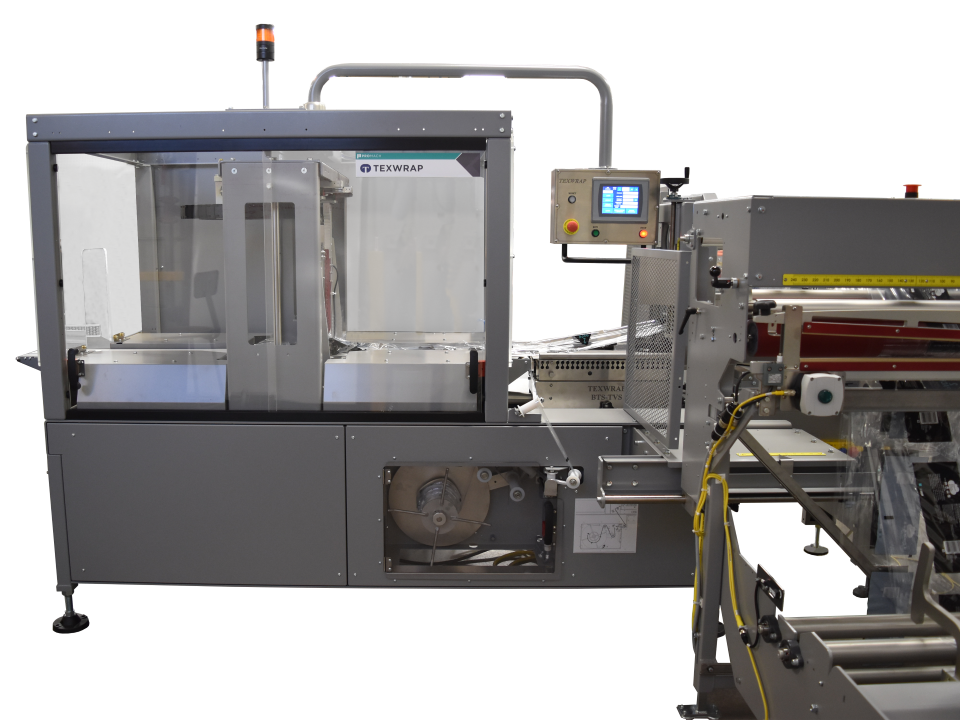

The EPSB-3322 e-Commerce solution creates a right-sized bag for product for both wrap-to-ship and wrap-to-stock applications. The EPSB-3322 can run opaque or clear film depending on the application. It can also be configured with an optional integrated ID Tech labeling system to print address labels.

A. Accurately measures dimensions of each product allowing an infinite number of SKUs to enter the wrapper.

B. TLS Series L-Sealer or CSS Series Side Sealer creates a right-sized film bag around input product for shipping.

C. Integrated Labeling System (optional) - For Wrap-to-Ship applications, ID Technology’s printer applicator is incorporated to print shipping labels.