ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFeatures & Specs

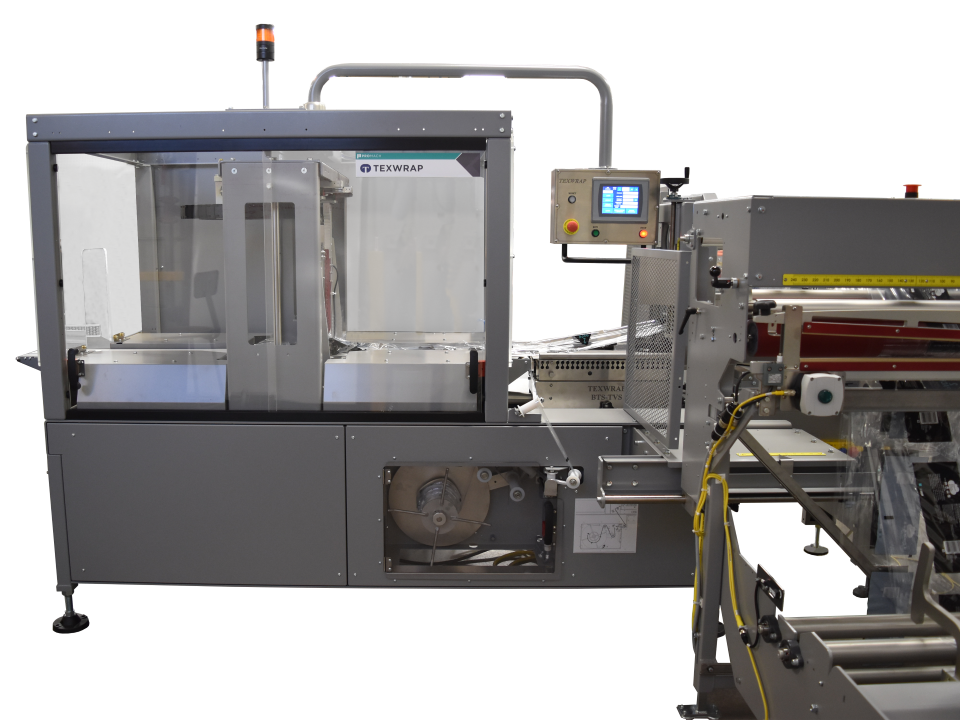

- Utilizes Texwrap's Patented Orbital Seal System resulting in highest rate of speed at continuous operation.

- Patented Texwrap's Versa Seal (TVS) bottom trim seal technology.

- 5-axis servo controlled seal jaws allowing operation at a higher rate and still maintain consistent, precision seals.

- Independent conveyor control allows relaxed film at cross seal and transitions.

- Upstream/downstream handshaking, feeder controls, optional quick connect cable system for additional equipment.

- Internal scrap take up with advanced oscillating guide, film break, take up reel alarms and quick release spool.

- Texwrap patented Motion Trim™ Technology that increases throughput by the running infeed and exit conveyors while seal jaws are in motion.

The model OVS-514 Continuous Motion Vertical Seal Wrapper uses a full bottom trim seal to securely enclose the product. In addition to providing an outstanding seal, this system eliminates the unsightly side seal across the side panel of packages common in other machines. Often used to wrap multipacks for retail sale, the precise product and film control of the OVS-514 allows high-speed operation with precise print registration.

The OVS-514 has a max product size of 6” W x 14” H and operates with a film speed of 200 feet per minute (FPM) and up to 135 cycles per minute depending on product and film type.

The model OVS-914 Continuous Motion Vertical Seal Wrapper uses a full bottom trim seal to securely enclose the product. In addition to providing an outstanding seal, this system eliminates the unsightly side seal across the side panel of packages common in other machines. Often used to wrap multipacks for retail sale, the precise product and film control of the OVS-914 allows high-speed operation with precise print registration.

The OVS-914 has a max product size of 9” W x 14” H and operates with a film speed of 200 feet per minute (FPM) and up to 135 cycles per minute depending on product and film type.

The model OVS-1418 Continuous Motion Vertical Seal Wrapper uses a full bottom trim seal to securely enclose the product. In addition to providing an outstanding seal, this system eliminates the unsightly side seal across the side panel of packages common in other machines. Often used to wrap multipacks for retail sale, the precise product and film control of the OVS-1418 allows high-speed operation with precise print registration.

The OVS-1418 has a max product size of 14” W x 18” H and operates with a film speed of 200 feet per minute (FPM) and up to 135 cycles per minute depending on product and film type.

The model OVS-1425 Continuous Motion Vertical Seal Wrapper uses a full bottom trim seal to securely enclose the product. In addition to providing an outstanding seal, this system eliminates the unsightly side seal across the side panel of packages common in other machines. Often used to wrap multipacks for retail sale, the precise product and film control of the OVS-1425 allows high-speed operation with precise print registration.

The OVS-1425 has a max product size of 14” W x 25” H and operates with a film speed of 200 feet per minute (FPM) and up to 135 cycles per minute depending on product and film type.

Texwrap combines its OVS Series Vertical Wrappers with automated infeeds and forced air convection shrink tunnels, to create fully automated shrink wrapping solutions. Our OVS Series is ideal for high speed continuous wrapping applications.

Texwrap’s OVS Series Side Seal Wrappers can be configured with an infeed from Texwrap to take the product from the upstream equipment and handle it to prepare the product to be wrapped and then passed through the shrink tunnel to fully automate the wrapping process. Texwrap has developed a variety of standard infeed designs or we can create a unique design depending on the application requirement. Our OVS Series Side Seal Wrapping Turnkey Solutions provide the customer with a complete solution to reduce or dramatically reduce manual labor required for the line’s shrink wrapping operations.

Features and Benefits:

- Configured solution with OVS Series Wrapper, Infeed and Shrink Tunnel

- FAT includes entire turnkey solution before installing at factory site