ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreThe market is demanding more and more packaging of products in multipacks. Many types of like items can be automatically grouped and wrapped for shelf display. Using printed film can produce a very attractive package while hiding individual bar codes and present a new multipack code. Texwrap even has a label-orienting system that automatically aligns the labels of individual items in a pack to face the same way.

Producing promotional packages can give marketers a whole range of new opportunities to increase market share. Examples include shrink wrapping in multipacks to include samples of new products along with current brands, BOGOs, or seasonal specials.

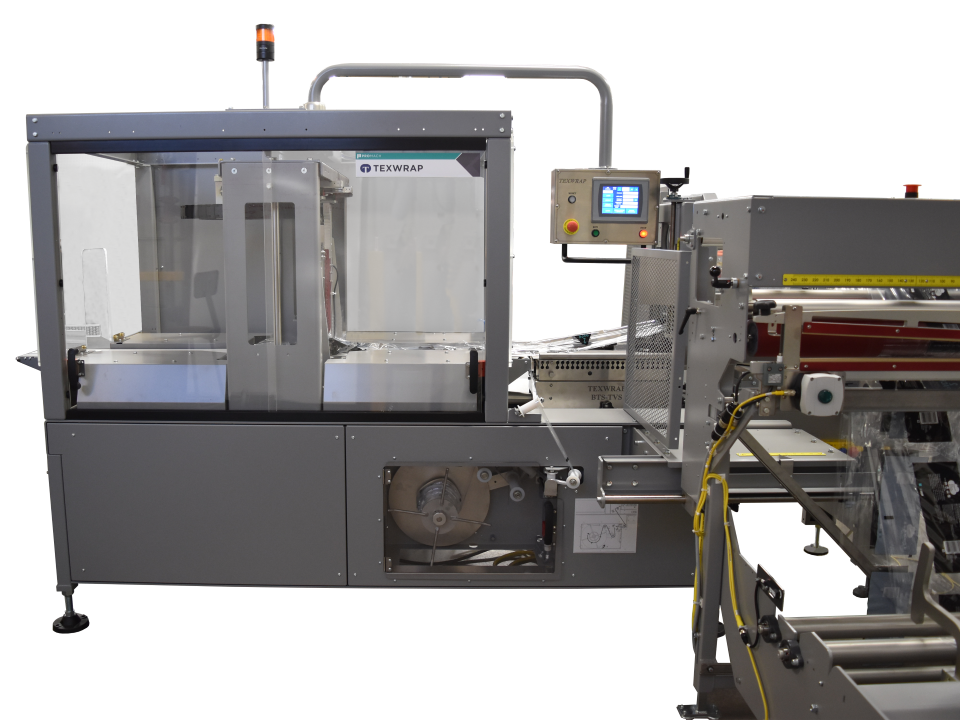

Texwrap’s automatic label positioning system is an important addition to our vertical wrapping systems offering. By combining it with a vertical wrapper, a multipack of products can now be automatically formed directly off a filler, arranged with the labels facing precisely the same direction, and shrink wrapped all while standing upright.The types of products that would typically be packaged this way are bottles, cans, canisters and jars.

The demand for vertical wrapping systems has increased with the growth in popularity of the retail multipack. This has been a boon as a marketing tool and also as a way to reduce the amount of packaging material. Texwrap vertical wrapping systems can eliminate the use of the carrier or "boot" commonly used to hold products together while being wrapped.

While most often used to orient product labels for increased shelf appeal, this unit can also be used to hide individual unit bar codes within a multipack.The package can then be labeled or wrapped with printed film for identification in the store as a multipack. As products are fed into the system in groups, the orientor automatically identifies the position of each individual unit. It then clamps each with a set with servo-driven wheels, spinning each one into the perfect position for wrapping.

The system is even flexible enough to combine multiple UPC codes or variations of the same product into a variety pack.

Texwrap’s automatic label positioning system is an important addition to our vertical wrapping systems offering. By combining it with a vertical wrapper, a multipack of products can now be automatically formed directly off a filler, arranged with the labels facing precisely the same direction, and shrink wrapped all while standing upright.The types of products that would typically be packaged this way are bottles, cans, canisters and jars.

The demand for vertical wrapping systems has increased with the growth in popularity of the retail multipack. This has been a boon as a marketing tool and also as a way to reduce the amount of packaging material. Texwrap vertical wrapping systems can eliminate the use of the carrier or "boot" commonly used to hold products together while being wrapped.

While most often used to orient product labels for increased shelf appeal, this unit can also be used to hide individual unit bar codes within a multipack.The package can then be labeled or wrapped with printed film for identification in the store as a multipack. As products are fed into the system in groups, the orientor automatically identifies the position of each individual unit. It then clamps each with a set with servo-driven wheels, spinning each one into the perfect position for wrapping.

The system is even flexible enough to combine multiple UPC codes or variations of the same product into a variety pack.