ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreSmall Bottles on Pucks

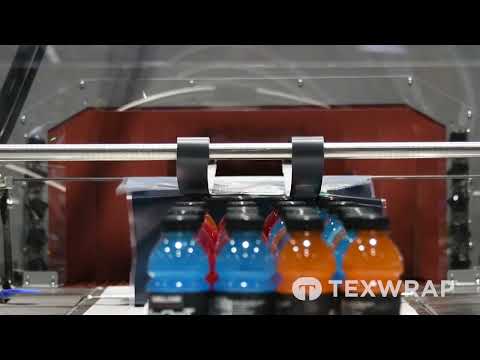

Containers arrive single file in pucks and 2 or 4 bundle patterns are picked and loaded onto the system in-feed conveyor. The flight assembly transfers the pack patterns through the webs of film across the continuous motion seal bar assembly and then are captured by the hold down system. Seal bars are activated to form film sleeves around the products and after the sealing process is complete, the bundles are transferred into the tunnel. The tunnel conveyor moves the bundles through the high efficiency split heat chamber and heated air is circulated around the bundles to shrink the film in a uniform manner. Bundles then exit the chamber and pass through the dual zone cooling stations and the shrink packaging cycle is complete.

The system also allows for non-bundled products to pass through the system via the by-pass conveyor.